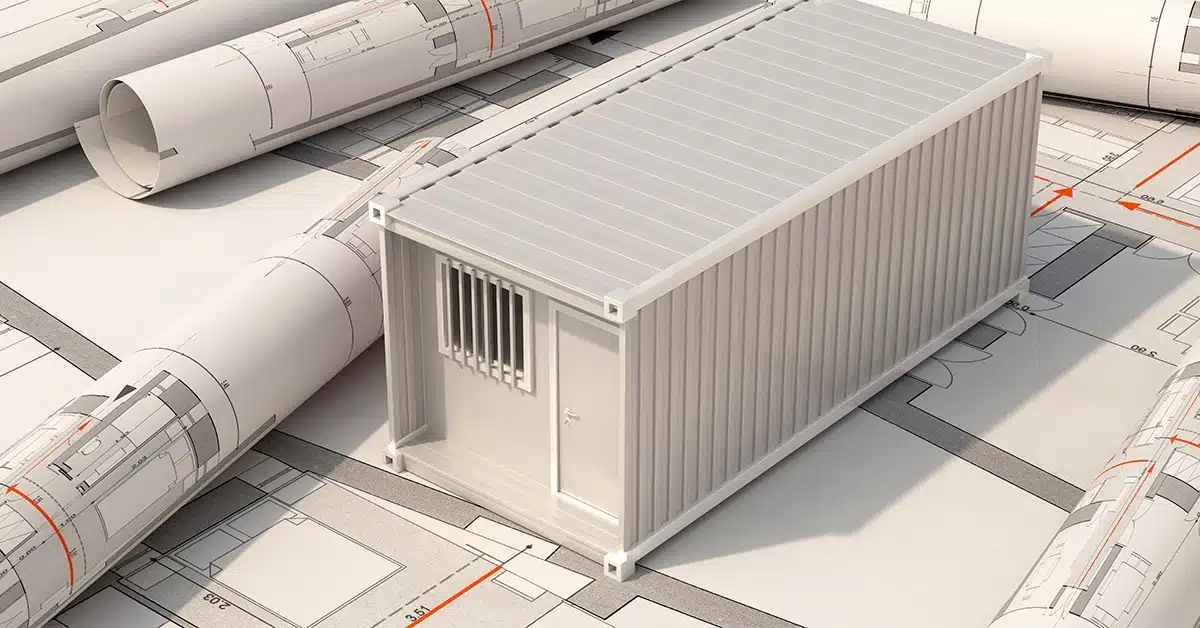

Prefabrication is an evolving building technique gaining traction fast in building construction. In most cases, it involves the off-site building of structures to enable quick assembly at the construction site. However, the designs can also get fabricated on-site.

It’s an incredible technology that helps to eliminate construction difficulties and allows for quick completion of projects.

This article looks at the advantages and disadvantages of prefabricated buildings in detail.

Benefits of Prefabricated Buildings

Reduce Environmental Pollution

Construction sites are inarguably one of the most significant contributors to environmental pollution. Brick, for instance, is the primary construction material used on most buildings, and its negative impacts on the environment are noteworthy. Brick burning alone emits a considerably high amount of GHG gases.

A 2015 TERI report revealed that the annual 170 billion bricks production consumes about 24 million tons of coal in India, emitting over 61 million tons of CO2. Further, steel and cement are other construction materials often used alongside brick, and they are also major emitters of GHG.

On the contrary, wood is the most commonly used material in prefabrication, significantly reducing GHG pollution.

Speeds Up Construction Process

One of the main benefits of prefabrication is helping you complete a project within tighter timelines. Ideally, all the parts arrive at the site partially constructed, so the remaining bit is just the assembly. As a result, there are minimal disruptions when the components get constructed off-site so that the assembly team can work faster.

The time frame can vary based on the complexity of a building, but typically, it takes much less time than conventional building techniques.

Cost Saving

As conventional construction costs increase, prefabrication is an excellent way to cost-save. First, the building technology uses low-cost materials like wood, plasterboards, and blocks of terraces, which are more affordable. Labor requirements and construction time are also reduced significantly, eliminating additional costs from inflation and climate change.

The entire process is easily manageable and significantly reduces material waste, and some resources are reusable. In any case, you can have a budget plan for the building with little chance of going out of the forecast.

Quality Construction

The production of fabricated structures happens in a controlled environment which allows for quality checks. Therefore, it is possible to check the materials’ standards and ascertain the mechanical technology applied. The construction oversight can also have qualified personnel specialized in various areas to eliminate errors and ensure job efficiency.

Proper planning helps avoid adverse weather conditions during fabrication and assembly, which can undermine the overall quality of the building. Besides, factory tools always provide better quality assurance than repetitive on-site construction.

Enhanced Safety and Security

In most cases, prefabrication happens in a factory and is majorly machine-intensive. The factory provides a systematic working environment that adheres to safety standards. The staff is reduced both at the factory and on-site, and everything happens orderly. That way, there are risks of congestion-related accidents. Also, the construction process is fast, reducing the vulnerability of materials to theft and vandalism.

Flexibility

In this type of building, contractors mainly deal with already built units, which provide high-level versatility in structural design. The designs have infinite possibilities, and changing them involves disassembling the units.

Also, it is easier and less expensive to correct errors made during construction, and there will be typically no material waste.

Disadvantages of Prefabricated Buildings

Prefabricated buildings have some considerable benefits but not without a few shortcomings. Here are some of the pitfalls associated with prefabricated buildings.

Choosing the Right Partner

When considering a partner for your prefabricated building, you want to make sure you’re choosing a reliable company to make sure all of your needs are met with the quality you expect. It is recommended to use a partner that offer turnkey services so you are not having to use your own personnel for a job that should be taken care of by the partner you are working with.

In the long run, the less you need to communicate with other parties involved the less headache you will experience. This includes any modifications or repairs that need to be made to your building over the years. Turnkey services can mean the difference between you finding someone to make repairs or making the phone call to company who manufactured the building to take core of it for you.

Possibility of Leakages

Prefabricated buildings have multiple joints where the different parts meet, and these are potential areas for leakages. In addition, if the assembly fails to achieve precision, the structure can have void spaces and joint issues. Leakages can then occur in these faulty joints and other faulty areas. Besides, the building naturally gets weaker with time, and leakages become inevitable. The best way to avoid these types of issues is to pick a manufacturer who fully encloses the building using welds and weather stripping to keep the outside elements from seeping into your prefabricated building.

Summing It Up

Certainly, prefabricated buildings provide a range of benefits compared to traditional construction. While they still come with a share of disadvantages, there are solutions for maximizing the benefits while keeping the pitfalls at bay. First, find the right manufacturers to ensure the material quality is good, and above all, engage qualified structural engineers. Having the right professionals who actively cooperate can make your prefab building quite a worthwhile investment. One should at all time seek professional information regarding the intended building before settling on the nature of the prefabricated material to acquire.