Population growth in urban centers strains the environment. Cities, especially large ones, produce a significant amount of emissions and waste products that damage the land and the atmosphere. Finding a way to reduce the negative impact of population growth in these environments is a priority for many communities. Modular construction could be one of the most effective ways to achieve this change.

It’s estimated that as much as 40% of landfill waste directly results from the construction industry. According to the EPA, in 2018, 600 million tons of construction and demolition waste was generated in the country, far more than any other type of material. This isn’t just a problem in the U.S., as about 36% of all global energy usage is directly related to construction materials.

Recognizing this concern, organizations and communities need to look at viable solutions. Consider why modular construction shouldn’t be ignored.

How Modular Construction Reduces Environmental Risk

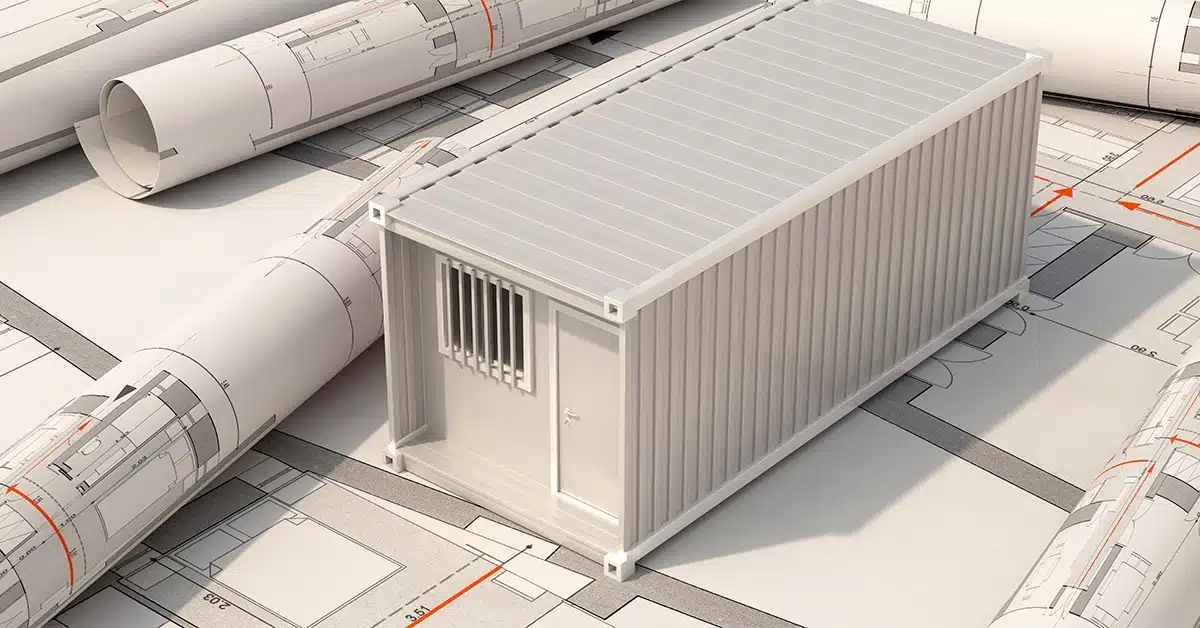

Modular construction is the building of large portions of buildings in a factory setting rather than on location. The components are then sent to the building location and assembled. This method can be used for many types of buildings, including residential and commercial spaces.

This type of construction process is seeing a lot of attention from builders looking for effective ways to build with fewer employees and, in some cases, in shorter periods of time to meet demand. In these settings, employees are less exposed to the environment, reducing injuries, and machinery can be used more readily to manage the more difficult components of the build process.

Yet, one of the most important reasons to make a switch to modular construction is because of how less damaging it is to the environment. Here’s how.

It minimizes waste

One of the core benefits of modular construction is that there is better control over inventories and materials. That directly leads to less waste produced. When a project has leftover materials, they can be repurposed for another project easily. That is much more difficult to do on a job site where product is often disposed of when it does not fit the needs of that specific project.

More so, in a factory setting, there is more control over those materials. They are stored within the factory, which means there is less overall risk for environmental factors to damage it. There are fewer moisture control problems that lead to damage. There is also less risk of theft in a secured factory setting than if those materials are sitting on a job site where anyone driving by could pick up materials they want to use.

Efficient timelines

One of the noted benefits of modular construction is the faster production process. That is good for the builder’s budget, but it also has an environmental benefit.

Most often, these buildings are completed about twice as quickly as an average traditional build. That means they use less overall energy to construct the same property. There is also far less environmental damage to the area during the construction project since it is done faster. There’s more overall control over the energy types used. Instead of driving heavy equipment to the area to handle the fabrication process, it’s all done in a controlled environment.

There are also fewer deliveries in factory-produced modular construction. Instead of constant deliveries of materials at various stages of the project, these buildings are delivered virtually ready to go. As a result of that, there are fewer trucks onsite and lowered emissions produced as a result. That drops carbon emissions significantly.

By being more efficient in terms of timelines, companies are able to reduce the environmental impact of the building process and the impact the building of a house or office building has on the immediate area surrounding it.

It’s possible to reuse

It’s already noted that modular construction enables companies to use more of their materials on hand from one project to the next. However, it’s also possible for organizations to reutilize modules. That means that the need for new materials for projects is lowered. That, in turn, reduces the environmental impact of the process.

Without a lot of modification, modular construction can continue to be used, even if changed or moved. That helps companies to reduce the cost of purchasing supplies, but it also means that there’s less demand for trees to be cut down or for fossil fuels to be used.

There’s less site disturbance

Most of the construction process takes place in a factory setting in modular construction. That means there is less need for these tasks to take place on the actual build site, reducing the overall impact on the earth and surrounding areas. With modular construction, companies do not need to have as much heavy equipment onsite. They may also have fewer people on site to manage the building process. All of that leads to less site disruption and less overall pollution.

Making a Move to Modular Construction Just Makes Sense

As demand for housing continues to rise, especially in urban centers, it is more important than ever for companies to consider their specific carbon footprint and to look for ways to reduce it. The same applies to large-scale commercial construction, which contributes so highly to landfill use and environmental hazards.

Modular construction offers numerous benefits. It’s more affordable for many organizations, enables a faster way to get projects underway and completed, and even protects the environment through its products. That makes it a viable solution for many communities.