“Along with operational changes, different environmental hazards have also propelled companies to use these prefabricated enclosures.”

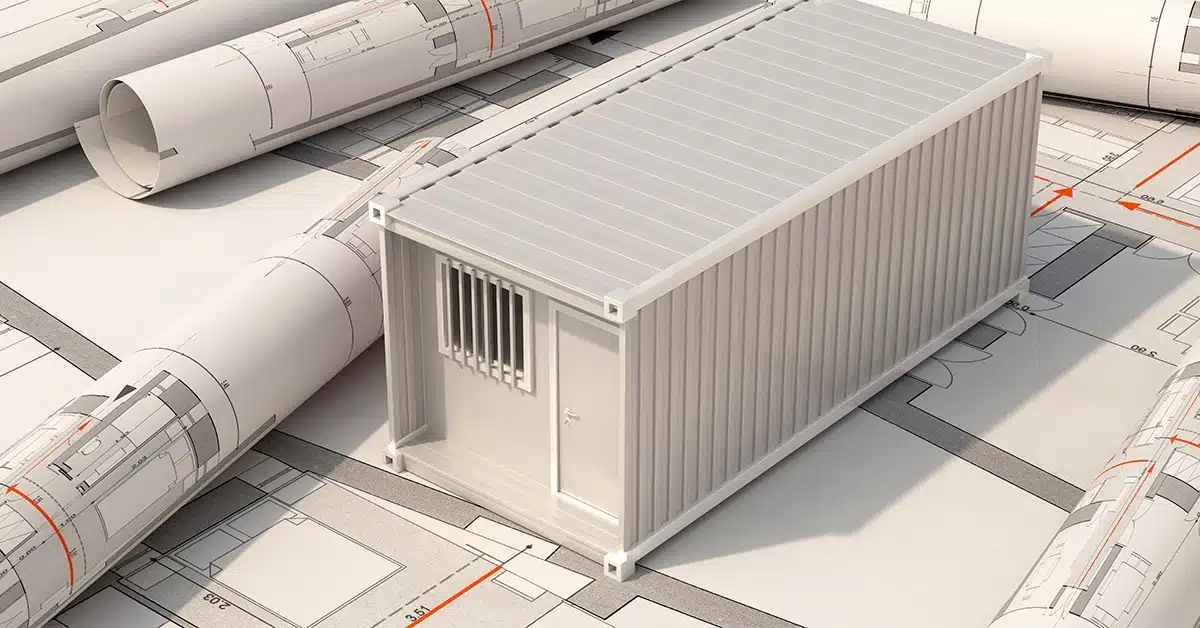

Prefabricated construction is becoming more popular, increasing efficiency, and is available on different budgets. Despite the perception of prefabrication, there are huge benefits to this type of construction. This article evaluates the advantages of prefabricated construction for the natural gas industry.

In recent times, the use of prefabricated construction in the natural gas industry has become incredibly common because it offers a number of advantages over traditional ‘on-site construction’ development methods. Some of these include the following:

Sound Attenuation

Controlling noise is difficult at the best of times and even more difficult when it comes to controlling the noise produced by the natural gas industry. The environment in which the natural gas industry operates is affected by distortions, reverberation fields and resonances that can lead to an increase in the level of the original source.

With so many different noise problems and ways to address them, it is always appropriate to use prefabricated buildings early in the design or expansion plan of the plant.

Explosion Proof

The natural gas industry works with hazardous substances or operates in hazardous locations, such as working with high-pressure systems, high-voltage electrical operations, and toxic gases, which can easily become chaotic under certain conditions. It is crucial that natural gas industries use explosion-proof buildings to create a safe environment.

Explosion-proof buildings help to ensure that all people working in this environment stay safe in the event of an accident and minimize possible harm.

Offer Protection to Staff and Equipment

If you work in natural gas industrial settings, you may be exposed to conditions that can escalate very quickly, leaving you with a very brief reaction time Equipment and workers involved in such settings must be shielded from any kind of event or damage that may occur due to a failed condition. Buildings provide dual safety for both people and equipment.

Flexibility & Cost Efficiency

Prefabricated buildings that cannot be shipping in once piece can be manufactured in modules and split into 2 halves, 4 quarters, or in any other configuration if needed. When your customized building is assembled on-site, we will ensure that it reflects the same design intent and specifications – without compromise.

The factory-controlled process generates less waste, creates fewer site disturbances and allows for tighter construction. Other advantages include:

- Reduced construction schedule

- Elimination of weather delays

- Pre-installed equipment to eliminate on-site installation

- Storing equipment that needs to be installed

Convenience

One of the most beneficial things is the higher level of convenience it offers. Added convenience takes a number of forms, including:

- Quick Installation

- Fire Suppression Systems

- Plumbing

- Alarms

- And much more

Ensures Success

There are many benefits to prefabricated buildings, including explosion-proof enclosures for the natural gas industry, as they involve hazardous conditions. If your safety measures are not up to the mark, the safety of your employees and equipment will be compromised and your valuable equipment can become damaged.

Additionally, our prefabricated buildings can be engineered to your particular installation location that will have all electrical components that meet NEC (National Electric Code). Buildings can be environmentally controlled with ventilation, AC, and heating based on site requirements whether the building is manned or un-manned. Consider the number of uses of prefabricated solutions in order to remain compliant with the workplace regulations.

Our years of engineering and manufacturing experience, full-service capabilities, and broad selection of customization options position us as the ideal prefabricated enclosure partner.

In order for enclosures to meet specification, they are assembled in a controlled and tested prior to shipping. Also, by welding beams together instead of using bolts, structural stiffness increases in order to resist tougher environments.

You can choose from a wide range of enclosures that we offer at the most competitive prices.

If you have an application for a prefabricated building, contact us to see how we can help. We’ll provide quick designs and quotes for the state you live in and include stamped drawings that can be submitted for building permits in your area.